A European-wide rapid prototyping offer

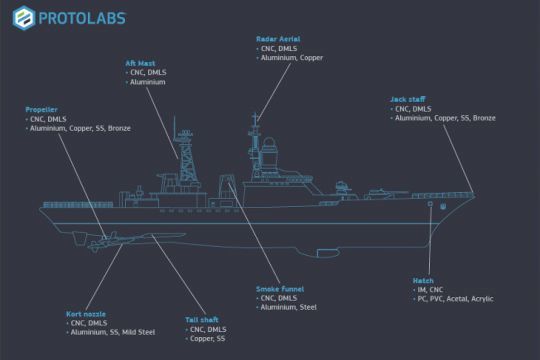

The American company Protolabs has several locations in Europe, in the United Kingdom, Germany and France for the production of mechanical parts. It offers various manufacturing methods for prototyping or small series: CNC machining and milling of metals, steel, aluminum, but also titanium or bronze and plastics such as polyamides and polycarbonates, plastic injection and 3D printing.

" Once an account is created, customers upload the 3D file of their part. An automatic analysis and a human control validate the feasibility. Our sales representatives get in touch and, if necessary, our application engineers discuss with the customer to make the part manufacturable with our processes. Once the part is validated online, lead times are very short: 1 to 3 days for machining, 1 to 7 days for 3D printing and 15 days maximum for injection "says Mr. Chang, Protolabs' Sales Manager for Southern Europe.

Expansion of the offer for the maritime sector

Already working on materials common in the boating industry in the plastic and metal fields such as bronze, stainless steel or titanium, Protolabs is now diversifying its offer. The company now offers the machining of 5083-H111 aluminum, the standard most used in the boating industry for its characteristics of resistance to the marine environment and salt water.

A supplier used to the nautical industry

Protolabs is already a familiar player in the marine industry on both sides of the Atlantic. It has worked with the Brunswick Group for Sea Ray boat parts. The company has also participated in the development stages of underwater lighting with OceanLED for injection parts. Alongside Pontos (whose technology has since been acquired by Karver), Protolabs has worked on plastic machining gear systems for the prototyping of 4-speed winches for the Malouin-based rigging company.