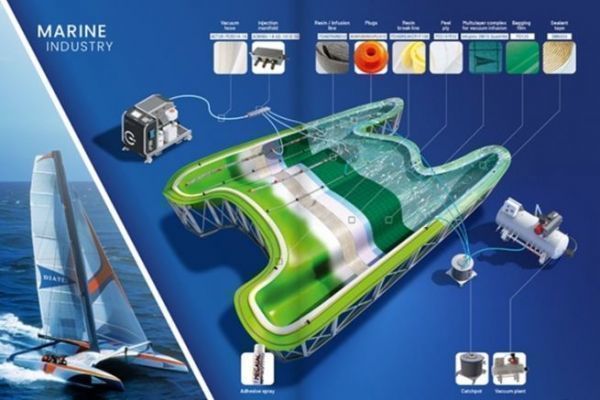

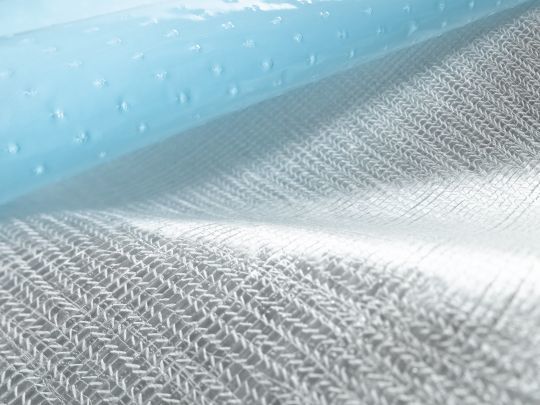

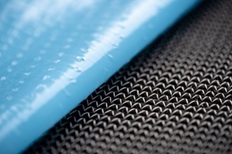

SAERfix is an adhesive developed by SAERTEX for self-adhesive multiaxial fabrics. It is pre-applied to NCF (Non-Crimp Fabric) reinforcements, enabling them to be draped directly into the mold. The benefits are clear: time savings and a significant reduction in material consumption.

Optimized production processes

In many production lines, fixing fabrics requires the use of large quantities of spray adhesive, a costly and time-consuming method. SAERfix, on the other hand, enables fast, clean application thanks to its self-adhesive properties. This speeds up the manufacturing process, reducing costs and material consumption. Layers can be easily and securely positioned in the mold, even on vertical surfaces or complex geometries, without the need for additional glue.

The uniform adhesive layer guarantees consistent, reproducible quality. SAERfix is also compatible with all current resin systems (UP, EP and VE resins).

Durability and high performance

SAERfix is not only an economical solution, it's also an environmentally friendly choice. It contains no aerosols and is classified as “not hazardous to water”. It also offers enhanced resistance to osmosis, which significantly improves the durability of the laminate. With an extended resistance at 60 °C warm water that lasts twice as long as conventional solutions, SAERfix guarantees sustainable long-term performance for all boat components.

An industry-approved solution

Numerous shipyards have already placed their trust in these tried and tested solutions, including Aventura Yachts, SAERTEX's latest reference in the marine sector. For the production of its catamarans, Aventura uses exclusively SAERTEX reinforcement materials, including SAERfix glass NCFs.

Integrating these products into their process has enabled Aventura Yachts to streamline production considerably, with faster draping without compromising on quality.

The main benefits of SAERfix

SAERfix is the ideal solution for boat builders wishing to improve their efficiency while focusing on sustainable, responsible quality. It enables more economical, resource-friendly manufacturing a decisive advantage in a highly competitive market:

-

Shorter production times: up to 50% less labour than traditional spray glue methods

-

Better materials management: reduced consumption and lower costs

-

Enhanced strength: superior durability

-

More sustainable: no spray mist, no solvents, no strong odours good for the team and the environment

With over 40 years' experience, SAERTEX helps manufacturers to optimize their production processes with customized, forward-looking and environmentally-friendly solutions, particularly for the marine industry.