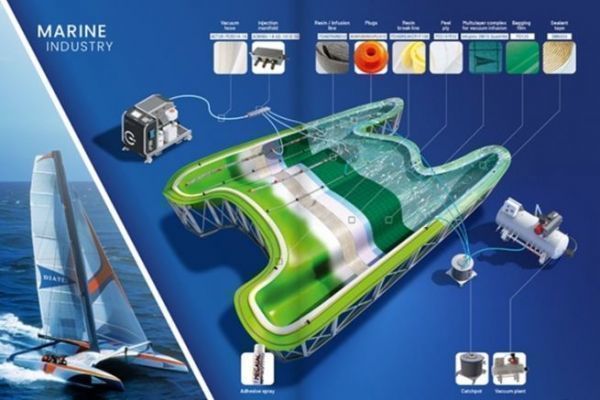

Diatex: French industrial excellence at the service of boatbuilding

In the demanding world of marine construction, every detail counts. When it comes to defining and implementing production processes, Diatex is an essential partner for boat builders seeking excellence and reliability.

- Made in France

- Recognized expertise in cutting-edge processes (Infusion, Injection, etc.) and high-value products

- A complete range of products from consumables to machines and reusable membranes

- Personalized technical support right from the project design stage

- A sustainable approach that meets growing regulatory requirements: recycled products, end-of-life management, sustainability, etc.

PES107 EV2: the tear-off fabric that prevents RSI, optimizes demolding and prepares a perfect bond for gluing

PES107 EV2 peel ply, developed by Diatex, prevents RSI (musculoskeletal disorders), optimizes demolding and prepares a perfect bond for gluing

It offers an innovative solution for limiting peeling effort while avoiding the use of additional chemicals such as silicone or PFas. Designed to improve working conditions for operators, PES107 EV2 allows the force required to be divided by 2.5 compared with conventional peel-off fabrics, making demolding quicker and easier. This reduction in physical effort directly improves manufacturing yields and reduces the risk of sick leave.

What's more, this polyester fabric requires no chemicals such as pfas or silicone, so it allows excellent quality bonding (deck/hull or bulkheads) with a more environmentally-friendly manufacturing process.

Diatex, the world leader in peel ply for structural bonding (qualified at Airbus and Boeing among others), has put its know-how to work for the marine industry.

With its compatibility with polyester, vinylester, thermoplastic and epoxy resins, PES107 EV2 is the perfect solution for vacuum infusion.

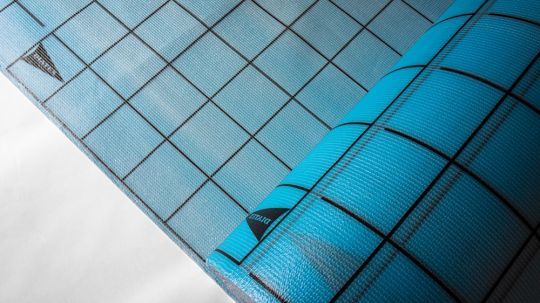

Infuplex Quadrille from Diatex: A productivity gas pedal

As the inventor of infusion laminates, Diatex is constantly working to improve the process. Diatex now offers a gridded laminate to save an incredible amount of time during draping. There's no longer any need to measure the gap between different resin ramps or vacuum. The grid (10 x 10cm) helps you work efficiently!

Designed with a two-layer drainage complex and a unique grid pattern, Infuplex Quadrille revolutionizes manufacturing methods. It offers not only substantial productivity gains, but also precise management of resin and vacuum ramps, while simplifying operation. The grid provides an "in situ" measurement of the distances to be respected in the infusion strategy.

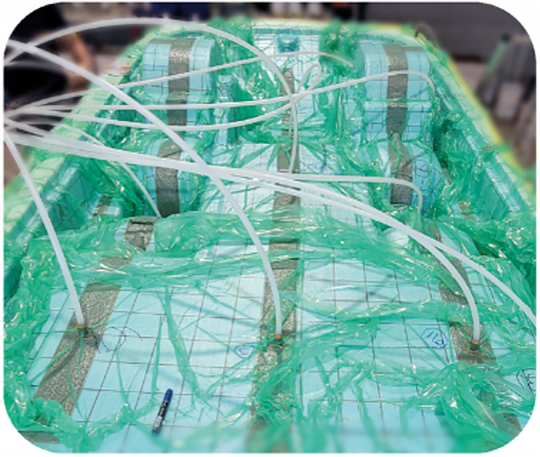

The welded PO120: Perfect joints for absolute reliability

When it comes to welding, Diatex guarantees impeccable quality for all technical projects. Welds are made with perfect precision, guaranteeing strong, tight and durable joints. They are designed to withstand the most demanding working environments while preserving part reliability. Each weld is tailored to project specifications, optimizing production processes and precisely meeting customer requirements. These welded tarpaulins offer widths unmatched on the market (up to 32 m), while retaining the quality of PO120 film.

A complete service for greater efficiency: Kitting

The kitting service is a tailor-made solution, designed according to detailed specifications. Kits are cut with optimum precision, ensuring reliable results in line with requirements. Thanks to advanced technology, Diatex also guarantees perfect part repeatability with every production run. In addition, optimized off-cuts maximize material utilization, reducing waste and improving costs. This kitting service considerably reduces part set-up and assembly times, accelerating production cycles.

The Diabreaker: The solution for more efficient and economical infusion processes

The Diabreaker is the solution for improving infusion processes. Extremely easy to use, it guarantees continuous vacuum and high-performance resin braking at the end of the part.

By slowing down the advance of the material as soon as it reaches the contact point, the Diabreaker prevents resin overconsumption and avoids filling pipes with excess waste resin, while maintaining good resin circulation, thus guaranteeing optimum vacuum quality.

Its demoulding quality means it can be used around the edges of parts or directly on composite parts.

The Diabreaker improves the brewing process, simplifying it and reducing costs, for a perfect result every time.