The problem of waste in the nautical industry is prompting many players to rethink boat design. In Vannes, Xavier Duveau is part of this dynamic with Saltenders, a company that relies on aluminum to manufacture 100% recyclable boats.

An alternative to conventional composite materials

With recyclability reaching almost 100%, aluminum offers a sustainable response to environmental challenges, while ensuring lightness and strength. The honeycomb plates used for the hulls guarantee optimum rigidity, comparable to fiberglass or carbon, but with far less ecological impact.

RIBs redesigned for durability

In hot zones, traditional RIBs have a limited lifespan. Once unusable, these boats often end up as waste. Saltenders offers aluminum models whose residual value is preserved thanks to the possibility of recycling. Users benefit from a solution that is both economical and environmentally friendly.

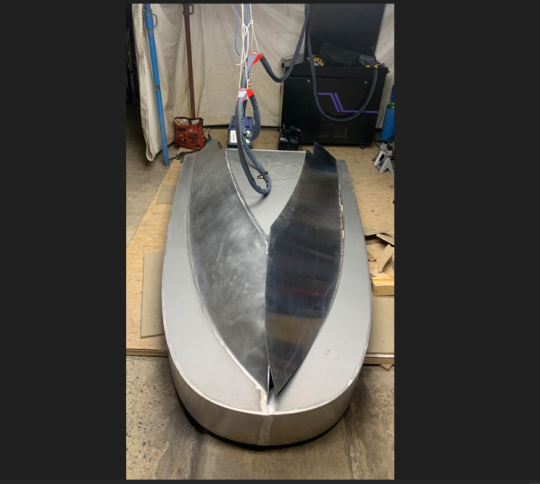

Production under test

Xavier Duveauâ??s pilot project, developed in a barn lent by a friend, illustrates the companyâ??s modest but ambitious beginnings. The two processes envisaged âeuros an epoxy/aluminum sandwich and âeuros a 100% aluminum sandwich âeuros are tested to optimize strength, weight and recyclability. The latter, heavier but more robust, could become an industrial solution thanks to the use of robots for welding.

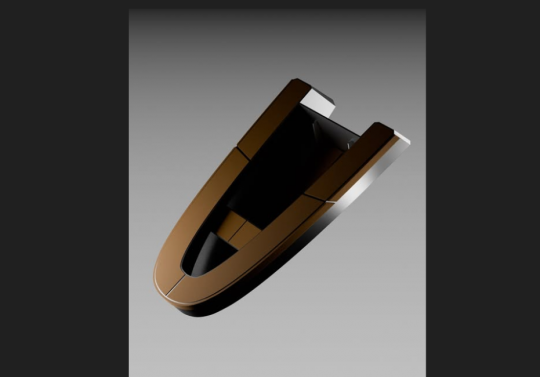

An adaptable, affordable range

Saltenders is planning a range of tenders from 2.70 meters to 4.20 meters. With prices estimated at between 6,500 and 12,000 euros depending on options, these boats are intended to be accessible to a wide public. The fact that no molds are required for their manufacture means that they can be fully customized, an advantage for yachtsmen looking for a made-to-measure solution.