Reinforcements with mechanical and drainage functions

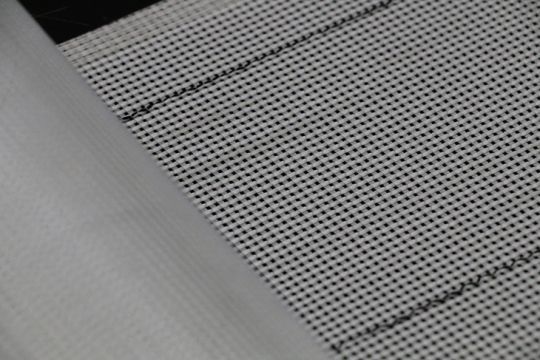

A recognized specialist in glass and carbon reinforcements for the marine industry, Chomarat has developed G-Flow™, a range of glass fiber reinforcements designed for infusion and RTM processes. Thanks to their patented construction, these fabrics combine a classic mechanical function with draining properties. Remaining in the final composite part, they replace the draining agents traditionally used in infusion and RTM processes. This range of 0-90° fabrics is available in 500 or 1000g/m² versions and in 125cm widths.

Industrial interest

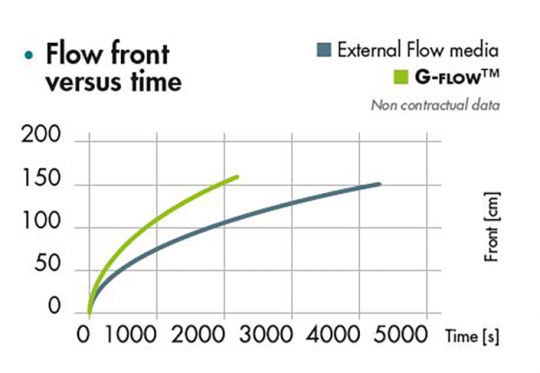

The use of G-Flow™ allows the shipyard or parts manufacturer a gain in productivity and cost containment. In fact, it saves on external drainers, and also reduces resin consumption. Vincent Cholvy, Chomarat's sales manager for the marine sector, states: "Customer studies show a 50% reduction in consumables. Generally speaking, we see a change in infusion strategy, with fewer infusion channels. No more resin is lost in the draining nets, so consumption is reduced."

The advantage of G-Flow™ also lies in part manufacturing time. There's no longer any non-structural fabric draping, as G-Flow™ participates in the structure. Operators can therefore drape the mold in a reduced amount of time. To further reduce this draping time, Chomarat offers to assemble G-Flow with another reinforcement (fabric, multiaxial, mat...)

To make the most of the advantages of G-Flow™, Chomarat supports its customers in implementing this new solution.

An ecological advantage

G-Flow™ is part of the development of infusion, a process that limits COv emissions into the atmosphere and improves working conditions. By limiting waste and resin consumption, G-Flow brings undeniable environmental gains for manufacturers.

Chomarat is also working on other eco-design parameters, such as the use of natural fibers like flax and hemp, and the integration of recycled glass or carbon fibers in its reinforcements.