Distinguish and clarify your activities

Seair was one of the first companies in France to work on foil-powered motorboats. Starting out with prototypes mounted on market semi-rigids and a foiling Mini 6.50 to create a buzz, the company made a name for itself in the sector and took part in various civilian and military projects, working alongside yachting manufacturers such as the Bénéteau group and the French Army. The variety of missions and services offered may have blurred Seair's image, so the company decided to create two entities, as Marketing Manager Jordane Ferreira explains: "Since November 2023, we have on the one hand the Seair Solutions design office, which delivers studies for various military sectors, passenger transport or yacht yards, and on the other hand Seair Flying Boat, which markets its own boats, built with the help of partners under our project management."

Boats for the luxury sector

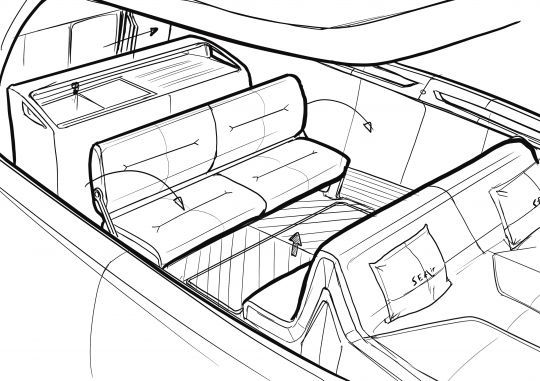

With Seair Flying Boat, the Lorient-based shipyard is moving resolutely upmarket, with the Flying Yacht 120 due to arrive shortly. This 12-meter foiling dayboat is aimed at the ultraluxury market," confirms the marketing manager, a Monaco Yacht Show veteran: "We're targeting the yacht or villa owner who loves innovation, research and comfort. With the FY120, we'll have a flagship in the water, plus a concept. It will then be a limited series, with the possibility of customization."

Romain Josset, Seair's naval architect, explains: "On the FY120, there are no compromises when it comes to flying at its best. Today, you can't want to be at 100% flight capacity and reduce costs. We worked on a dedicated hull, power regulation and controls for various systems for good flying ability."

A design office to optimize energy efficiency

The design office teams, who continue to work on "in-house" boats, will be able to take advantage of the experience acquired for external customers. Over 3/4 of Seair's 18 employees work in the design office, with specialties in CFD, structure and systems. They are capable of working on all types of optimization of a boat's consumption and comfort," emphasizes Romain Josset, who is not limiting his work to foiling. "We do optimization in general. We have the appropriate software suites and a simulator that we have adapted in-house. For the foil, the aim is not to go fast, but to reduce consumption. You have to look at the ecological aspect. On the FY120, we've managed to reduce fuel consumption by 50% compared with an archimedean boat."