Seamlessly inflated systems

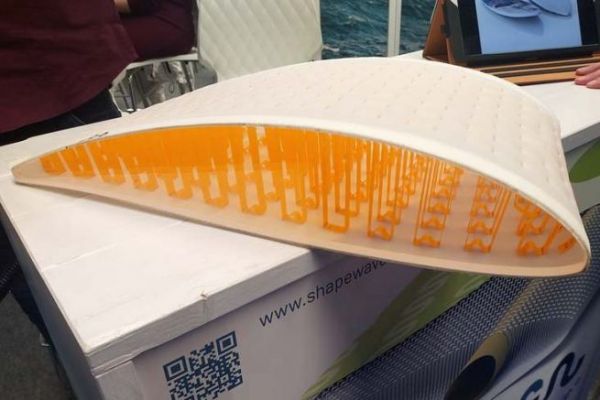

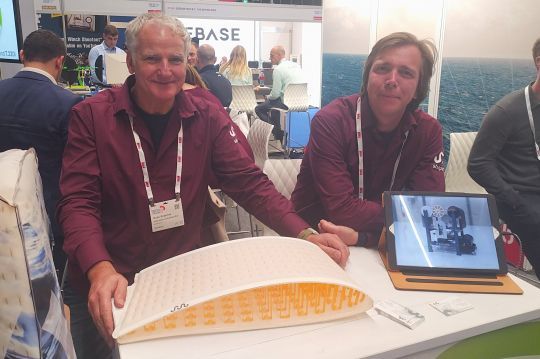

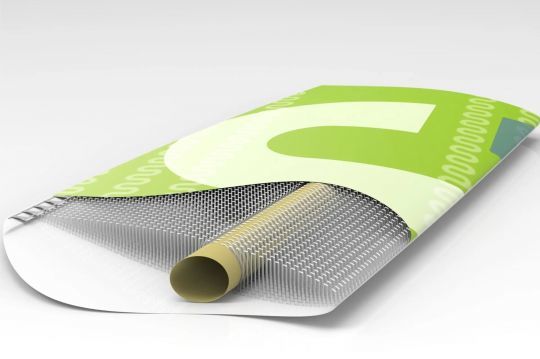

Inflatable structures are nothing new. Giving them a variety of shapes with good rigidity has become common practice, in particular using the drop stitch system, which consists of maintaining tension between walls using sewn-in internal threads. Dutch start-up Shapewave, founded by Rudo Enserink and Dominique Kwaks, offers a new alternative solution using welded ribbons. Rudo Enserink, creator of numerous objects, from composite guitars to the Gunboat G4 catamaran for which he collaborated on the design, came up with this technology that enables pressures of up to 1 bar to be reached in 2018, until a patent is filed in 2020. He has teamed up with Dominique Kwaks, already familiar with the kitesurfing industry.

Shapewave technology offers a number of technical advantages. The spacing between bands can be reduced to just 10 mm, offering homogeneous shapes. The absence of seams ensures that the object remains watertight, which can be a problem with drop-stitch. Finally, Rudo Enserink highlights one last advantage: "We're less expensive than a conventional inflatable system."

A wide range of applications

Inflatables are popular in many fields, but these two water-sports enthusiasts see them as their first natural outlet, as Rudo Enserink explains: "We can imagine wingfoil wings, boards, traction kites, but also boat wing profiles, like for the A Class boats I race on. We can position the ribbon around internal structures like a mast."

An industrial process to propose

Initially, Shapewave will be demonstrating applications through a range of products, but the start-up's aim is to sell an offer ranging from the design of the object, its manufacturing mode with ribbon positioning, to the sale of the production tool with ribbon welding machines for robotized product manufacture.