High performance epoxy resins

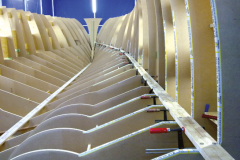

The Pro-Set brand offers a wide range of epoxy resins for the manufacture of composite parts. Intended for vacuum lamination and infusion with a high level of performance, they are progressively proposed in biosourced versions up to 30%.

In order to simplify the use by the operators, the resin range is used with a common hardener. A slow hardener and a fast hardener, of the same viscosity, are mixed in different proportions to obtain 4 basic curing speeds. "If needed, we can vary the mix to precisely adjust the speed to the job site need." reports David Jaffeux of Directeck, Pro-Set's importer in France.

Depending on the choice of resins, the manufacturer can adapt the viscosity to his needs. A unique mixing ratio of 1:3 across the range avoids confusion.

All Pro-Set resins require a post cure. The high temperature resins require a post cure at 85°C, while the others require only 8 hours at 60°C. "We cook for less time and less heat than average which brings a gain in production speed and cost" emphasizes Directeck.

Precise collages

The Pro-Set catalog also contains ADV adhesives. Available in translucent or black, they are particularly suitable for precise bonding or hull-deck connections on boats. The adhesives are supplied with mixing cartridges. "We can choose the setting time depending on the work to be done" says David Jaffeux.

TLG Coatings

Particularly interesting for boat repairs and superstructure or mold coatings, Pro-Set also offers epoxy-light coatings called TLG. With a low density, they are used by major boat builders.

Manufacturing and training in Europe

Pro-Set products are manufactured by the Goujeon Brothers group, renowned for the West System range. The resins are produced in the UK, which has its own technical center. "There is real technical support and training for customers in the UK." underlines the French importer, Directeck.