Epoxy composite panels

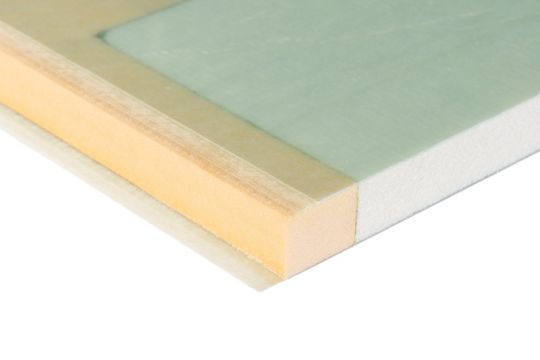

Developed by a distributor of West System resins, the Duflex brand has made a specialty of prefabricated composite panels. Laminated with high performance resin and multiaxial glass fabric of 300g/m² or 2x300g/m² and protected by a removable layer that avoids contamination and reduces surface preparation time, Duflex panels are offered with different core materials depending on the use.

The customer can choose different density of foam, balsa or honeycomb depending on the weight, structure and equipment of the boat. A final tear-off fabric is integrated for installation on board the boat.

Easy to implement

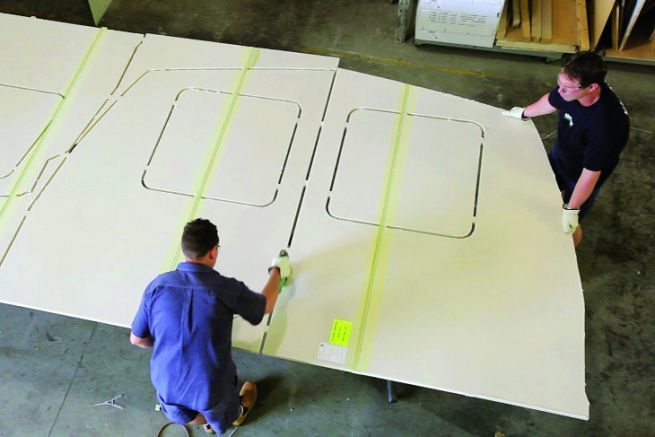

Once the elements have been received, they can be laminated for the manufacture of the boat, which can be used to build an entire boat from A to Z, from the hull or deck plating to the fittings, including the structural partitions, by varying the characteristics of the material.

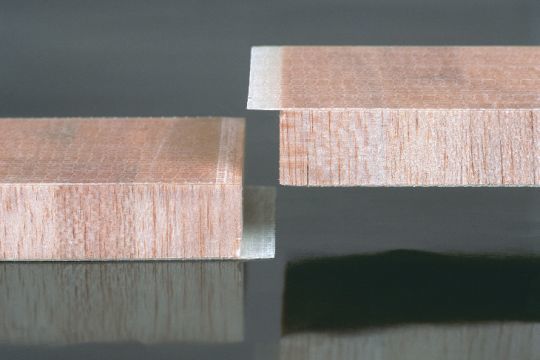

Corner connectors are provided for epoxy bonding.

A Z-shaped assembly system makes it possible to assemble the elements together, in particular to constitute large partitions from pre-cut elements.

To produce rounded parts, core cut-outs are possible.

"The use of Duflex panels combines economic and organizational advantages, with time savings compared to the in-house production of the elements on site," says David Jaffeux of Directeck, the brand's distributor in France.

Products adapted to the needs of the site

Depending on the builder's choice, Duflex panels can be delivered as raw panels to be cut by the builder or pre-cut with the Z-joints determined from the boat's dxf file. Duflex thus optimizes the layout to limit material losses.

For construction sites looking for performance and lightness, Duflex also offers honeycomb panels with carbon fiber outer skins.