Single-use tools

To build a composite boat in series, it is most often to make a mold. And even before this, to make a master part. If the mold, in the best of cases, is used to manufacture several tens of boats, the mother part is for single use. At a time when our society has to think about its waste production, the situation is not very good.

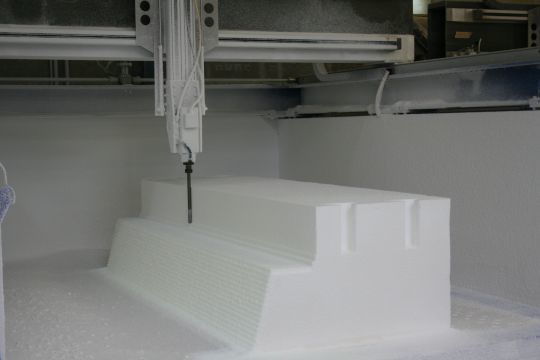

Specializing in the manufacture of molds for composite parts, particularly in the nautical industry, the company from La Rochelle, Formes et Volumes, has looked into the matter. "Historically, when we made the mold on the mother part, it goes to the trash. A truck crane comes with a grapple to destroy it and it goes to the standard waste disposal center. So we thought of a dismountable solution to recover the polystyrene" explains Gaël Lacord, technical manager of the company.

Reuse of the material of the mother parts

The mother pieces are made of polystyrene blocks assembled, then laminated and coated. "Before, everything was glued and unmovable. Here we changed the type of glue, the system of interlocking and instead of gluing everything strongly and then laminating it, the blocks are barely glued and we laminate as we go along. Thus, we pollute the polystyrene as little as possible. For the deconstruction, we peel off the stratification and we cut it with a hot wire. Thus we can recover 80% of the polystyrene in large cubes that we reuse for other mother pieces and the remaining 20% are crushed for recycling" says Gaël Lacord.

A virtuous but expensive solution

From a performance point of view, the method is perfectly competitive. "In terms of metrology, we have the same dimensional requirements" confirms the technical director.

From an economic point of view, it is unfortunately not the case, but Formes et Volumes assumes its choice inaugurated for a mould of Neel Trimarans. At the current price of polystyrene, the labor time for cutting and reuse is not competitive with the use of new polystyrene blocks. A reflection on the life cycle analysis of the boats will certainly have to be carried out to make these costs acceptable and shared and to value these virtuous initiatives.