Meet all the needs of boat builders

A recognized player in the teak sector for boat decks, the Directeck distributor began a few years ago to diversify its offer in the field of composite materials. After starting with the West System brand, its resins and fabrics, the company has gradually expanded the range of products offered by adding new brands to its catalog: Pro-Set, Pro-Vac, Duflex and Entropy. It can now meet almost all the needs of construction and repair sites, from fabrics to resins, including consumables and accessories for infusion and vacuum bonding.

West System for resins and fabrics

West System epoxy products were developed over 50 years ago by Goujeon Brothers Inc. for the production of wooden boats. They cover a wide variety of uses, from coatings to adhesives, thanks to the choice of several hardeners and 8 different types of fillers.

In addition to resins, which are also suitable for use outside of wood construction, we also offer fiberglass fabrics for composite parts.

Pro-Set and Entropy for high performance and durable resins

Another Goujeon Brothers brand, Pro-Set is positioned as a premium product with a high level of performance. Pro-Set epoxy products are suitable for both infusion and contact and are suitable for high temperatures with very good cure profiles. They are resistant to hostile environments. They enable quality assemblies and the manufacture of clear coatings. The Entropy range, which joined the group in 2018, develops partially biobased resins.

"With the Pro-Set range, it is possible to have good control over the application, by choosing the resin according to its viscosity and the hardener for the speed of polymerization. Entropy resins, with their low viscosity, can also be combined with different hardeners to control the speed of polymerization. Today, Entropy resins are up to 30% organic," says David Jaffeux, Directeck's CEO.

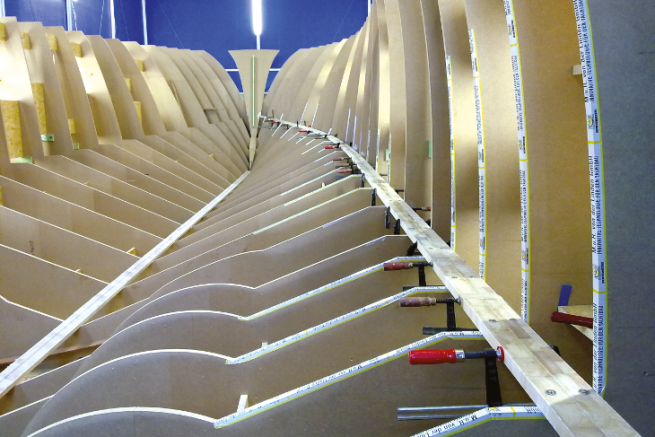

Duflex for composite panels

With the Duflex range, Directeck is able to offer flat composite panels already laminated in epoxy with one or two 600 g/m² fiberglass outer skins. With a core of balsa, divinicell foam of different densities or honeycomb, they can be delivered already cut according to the 3D model of the boat.

Thanks to pre-made Z-joints, the panels can easily be assembled by the yard with few operations. "There is a saving in time and machining that is already attracting a number of boat builders," says David Jaffeux.

All the peripherals of infusion manufacturing

With the Pro-Vac range, used in the wind turbine industry, Directeck offers infusion equipment for all sizes of parts, even the largest. It includes all the elements required for vacuum processes, from vacuum bags to tear cloths, drainage nets, separation films, sealing compounds, as well as polyethylene piping, valves and connectors.