Matthias de Christen took over as head of Incidence Group's sailmakers in December 2019. He looks back with BoatIndustry on his 1st months at the helm of the company in a nautical sector agitated by the Covid and shares his vision for the company.

Can you come back on the highlights of Incidence Sails since your arrival?

I arrived in very special conditions! There was a sudden halt in sales with the pandemic in March 2020, and the recovery has been very heterogeneous depending on the market. There has been a surprisingly rapid recovery in the aftermarket for pleasure boats. For original equipment manufacturers, which represent 50% of Incidence Sails' business, it is also heterogeneous, some have returned to pre-crisis levels, others are having more difficulty finding an industrial rhythm. For the niche shipyards with which we work a lot, the challenge is more to replenish the order book in the longer term. Their clientele has been little affected.

The other effect of Covid for us is the tension on all supplies worldwide. We get 95% of our supplies from France and Europe, but we are affected in terms of fabric purchases because our suppliers are having difficulty obtaining supplies of polyester, dyneema or aramid fibers and resin for membranes. We saw it coming, but not to this extent. It has gotten worse in the last 6 weeks. Cost inflation could become a problem.

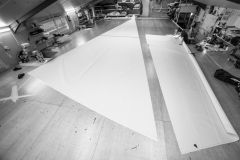

There was also good news in 2020, with the success of the Vendée Globe which we obviously followed. We moved to our new premises in La Rochelle in June 2020 on a 3500 m² floor, the 2nd largest in Europe. We managed to switch all the production in 4 days. This production tool and its new machines will allow a real gain in competitiveness and help to develop the Made In France.

What are the current investments for Incidence Sails?

The new floor of Lorient, of more than 350 m² should be operational in the coming weeks. On the side of Incidence Technologies, we have decided to make a massive investment of more than 1 Meuros to develop the production capacity of the Dfi membrane. We realize an upstream integration on the manufacturing, with an impregnation line to make the necessary tapes for the production of sails. We gain in capacity and reactivity. The Dfi membrane has a future in ocean racing, but not only! Also in IRC and racing-cruising.

What differences have you seen with your industrial experiences?

I come from a packaging background, both in family businesses and in large groups. I think that there is still room for improvement in terms of efficiency and process, but I am aware that we must not lose sight of the specific needs of each client and the very different levels of demand between yachtsmen, ocean racing teams and shipyards. You have to know how to keep the Swiss Army knife aspect of the sailmaking business. Sails will never be an industrial product.

What are your major upcoming projects?

The 1st axis is to continue to develop the Made In Fran,ce, which is a real challenge. The second is to continue to think sustainably. Sailing is sustainable in itself, but we need to go further, with recycled and bio-sourced materials, recycling of old sails, short circuits. We already have our sails delivered in France, which leave with the shipyard's boats. The last axis is to make the Incidence Sails brand better known outside France.