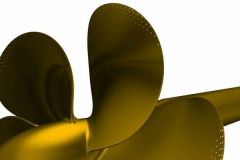

A 5-blade propeller printed in 3D

The Indret site of the French naval ship specialist, Naval Group, has delivered a non-standard propeller. Composed of 5 blades of 200kg each and with a wingspan of 2.5 metres, this propeller was built in additive manufacturing, more commonly known as 3D printing. It now equips the Andromeda minehunter, a 52-metre vessel.

An economic and design interest in propellers

The propeller of the Andromeda was manufactured using a 3D printer, which remains exceptional to this day. "We are the only manufacturer in Europe to have a metal additive manufacturing machine based on the WAAM process with a very high capacity. The cell is 20 meters by 10 with two robots" says Naval Group. WAAM (Wire Arc Additive Manufacturing) makes it possible to weld metal wires of small dimensions.

The propeller is the result of a collaboration between Naval Group and the Ecole Centrale Nantes, started in 2017. "Nearly three years of R&D, carried out by the Technical and Innovation Department with the Ecole Centrale Nantes within the framework of the LabCom Joint Laboratory of Maritime Technology, were necessary to qualify the process of material deposition by wire fusion," explains Emmanuel Chol, Director of the Nantes-Indret site. "Today it is a world first. It is the largest propeller to be made in additive metal fabrication and it is the first propeller produced using this technology, on board a military ship and manufactured to go beyond sea trials"

Naval Group will devote 7 Meuros in 2021 to additive manufacturing. The savings in production time and cost of materials for small series, compared with casting, which requires moulding, and the freedom in the geometries of the thrusters may eventually be found in yachting.