In 2019 Wichard celebrates its 100th anniversary. The forge located in Thiers produces quality fittings. We met Jean-Claude Ibos, President of the Wichard Group, during a visit to the company's facilities. He explains the origins of the company and the perspectives of this group.

Wichard's W1 site in Thiers

From knife to fittings

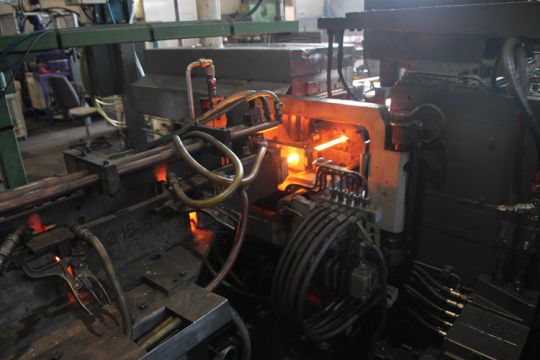

Wichard was originally a forge for cutlery. It was only in the 1970s that it developed in the nautical industry by manufacturing shackles and carabiners. The use of the forge, compared to the foundry, reinforces the mechanical capacity of the steel. Forged parts do not break under stress, but deform. The foundry, which is cheaper in production, produces parts that have no fibre, but only grains. The breakage is done by rupture, without warning.

Like many boating companies, Wichard suffered the crisis and had to adapt. However, if in 1998 the turnover was 8M, it rose to 16M for 2018 excluding subsidiaries. This company is progressing largely in export which now represents 50% of the turnover. For 2018, the Wichard Group's turnover is ?30 million.

The automatic forging process

Service provider for other brands

Today, to diversify, Wichard produces forged parts mainly for the nautical industry under the Wichard brand, but also develops mechanical parts (automotive, aviation and mountain equipment, among others...) and for other suppliers.

Wichard W2 site with manual drumsticks

Growth through repurchase

Given the stability of the market, Wichard is developing with external growth through the acquisition of companies. So after Facnor Sparcarft, it is Lorima and Peguet's turn to join the Wichard group. This growth is not over yet, as Jean-Claude Ibos announces that in 1 to 2 years' time, 1 to 2 companies could still join the Group.

All these companies stand out for producing quality products in the mid- and high-end segment. There's no way we're going to do low-cost.

The manufacture of shackles, many manual operations

Everything for the deck layout

The Wichard Group's objective is clearly to become a key supplier of deck plan equipment. After the deck fittings, masts and reels, it is not difficult to imagine that the group will seek its expansion towards manufacturers of deck panels, cleats or even ropes. Jean-Claude Ibos even admits to having followed the Pontos winches file very closely, which was finally bought by Karver. But other opportunities are expected to emerge in the near future. To be continued..