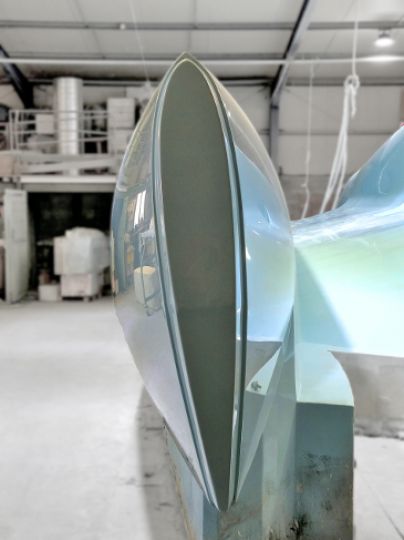

Manufacturing process of the Neel 47 mold

The construction of molds for the production of sailboats in series requires a real know-how. For the manufacture of the tooling necessary for the production of the hull of its new multihull, Neel Trimarans turned to the Rochelle-based specialist Formes & Volumes. The company works for many players in the yachting industry in the region.

For the Neel47, they made two separate mother pieces, each including a central half-hull and a float. They will allow the production of two female molds, each corresponding to a half-boat. The 2 elements will finally be assembled in the new buildings of the Neel Trimarans shipyard, in the port of La Rochelle, which will then have a complete tooling for the production of the hulls of the new boat. The final piece will measure 15 meters long, 8 meters wide and 3 meters high.

A new trimaran by Lombard

As a reminder, the new Neel 47, announced at the beginning of 2018, is signed Marc Lombard. It features the brand's essential elements, through the large owner's cabin at saloon and cockpit level and the Cockloon (Cockpit/Saloon), a concept that combines the saloon and cockpit into one space thanks to large sliding opening bays. Retractable partitions will give the owner the impression of being in his bed in the middle of the water and the boat, as in a loft without partitions.

Production should begin in the summer of 2018 to allow for a presentation of the model at the 2019 Grande-Motte International Multihull Boat Show.