In early summer 2017, you announced the creation of Nordac 3Di, the dacron version for the 3Di cruise, a product already well installed on racing yachts. What are the first commercial returns?

Luc Joessel : The first sails have already been sold in France and we have reached an entirely new clientele for us. For example, I have already delivered sails for old boats like Samourai or Tequila Sport, which are sailing boats that we would never have touched with our previous products. We'll see after the fall shows, but it looks very good.

Luc Joessel, Marketing Manager, North Sails France

What makes the difference between a Nordac 3Di and the rest of the 3Di range, from a technical and economic point of view? Where does the price difference come from?

Greg Evrard: The technical process is exactly the same and is based on the same patents, inherited from America's Cup experience and North Sails know-how. Only the material changes. The filaments deposited in the 3Di were until now a mixture of Aramid and Dyneema, with sometimes an addition of carbon. In Nordac 3Di, it is polyester, the classic dacron.

From the mechanical and aerodynamic point of view, we have the gains linked to 3Di, with the absence of sewing and cutting. The shape is incomparable with a classic dacron panel sail.

In terms of price, the gains compared to 3Di Aramide-Dyneema are obviously made on the material, a few dozen times cheaper, but also on design time and equipment. A cruising sail is often less equipped and optimization calculations are more limited and simpler with only one type of fiber in the Nordac 3Di.

With which sail should Nordac 3Di be compared?

Greg Evrard: It is very difficult to compare it, because it is of a much higher quality than a dacron sail with panels. It is between the latter and a 3Di Aramide-Dyneema sail. In terms of price, we are slightly higher than the North Sails panel sails (NDR: on the cruise catamaran tested by BoatIndustry, the price of the Nordac 3Di announced by North Sails is 19% higher than that of the sails in dacron panels of the sails)

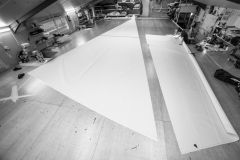

Genoa in 3Di Nordac

How do you see your positioning in the cruise market?

Greg Evrard: It's quite paradoxical. Excluding sails for construction sites, North Sails is the world's leading sailmaker. Nevertheless, we can analyse ourselves as having been very bad in the cruise segment up to now. With Nordac 3Di, this is the first time in 60 years that North Sails has done research dedicated to the cruise market. The objective is to find and retain customers, as we have done in the other segments. We don't want 100% of the cruise market!

Are you considering agreements in the original equipment sector with construction sites?

Greg Evrard: Why not, if the yard is willing to put up the price for the product. For production, arrangements can be made with the availability of mussels in Sri Lanka.

Will 3DL disappear?

Greg Evrard: With 3Di's offer, we cover all navigation ranges. The main disadvantage of 3DL is that it can delaminate, a problem solved by 3Di. So what's the point of continuing? Nevertheless, we are continuing for the moment for the classes of boats that prohibit 3Di.

What are the future innovations of the sailmaking?

Greg Evrard: There are surely still future technical variations of our methods. Why not wire spinnakers, even tear-proof? With the arrival very soon in Vannes of an R&D centre for the entire North Sails group, we should see some progress!